by Rob O'Byrne | Jan 7, 2025 | Cost, Cost Saving, Inventory - S&OP, logistics, Slotting, Videos

It’s incredible how often businesses lose money on customer orders without realizing it. The root cause? A lack of visibility into customer and product profitability. Over time, this can lead to significant profit leaks across supply chain and logistics operations....

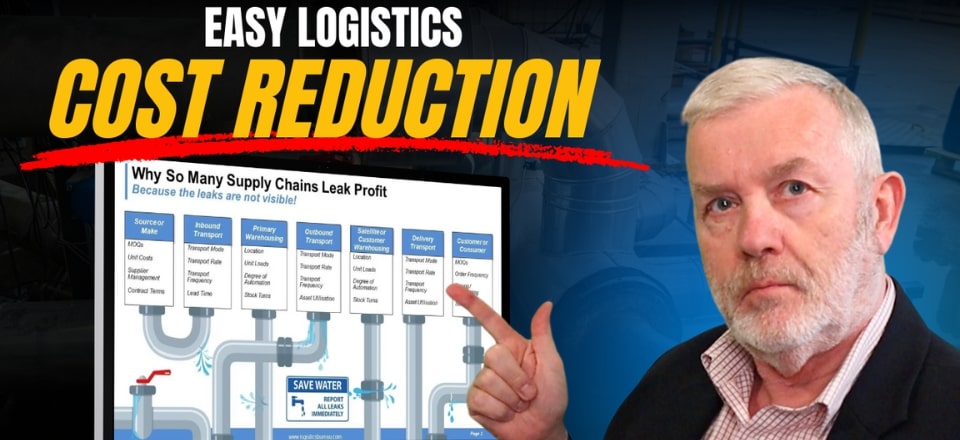

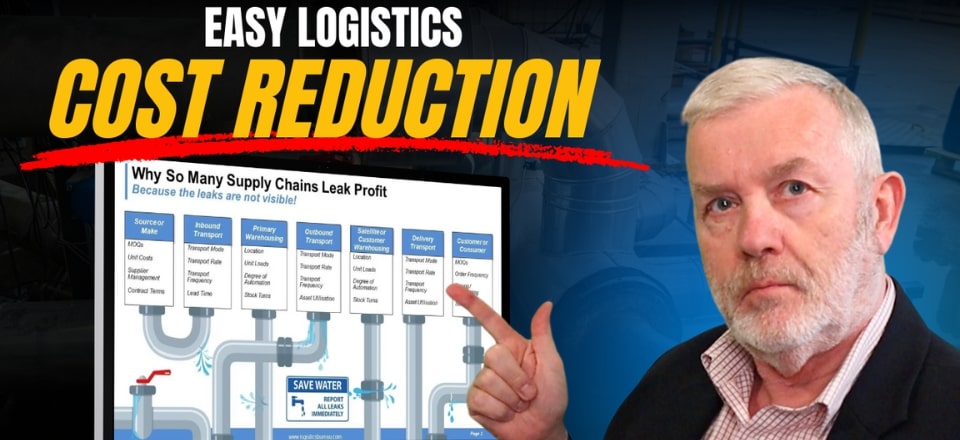

by Rob O'Byrne | Dec 17, 2024 | Cost, Cost Saving, logistics, Videos

Reducing logistics costs can feel like a never-ending challenge. With so many areas to consider—transportation, warehousing, inventory, and more—it’s easy to feel overwhelmed. But instead of trying to solve everything at once, focusing on some specific area can...

by Rob O'Byrne | Aug 13, 2024 | logistics, outsourcing, Videos

How long do you think it should take? This question has been posed several times. The answer, as always, is not straightforward—it depends on a variety of factors. Watch the video below as I illustrate with a couple of straightforward case studies: one that involved a...

by Rob O'Byrne | Jul 16, 2024 | logistics, outsourcing, Videos

Efficient logistics operations are critical in today’s competitive business landscape, offering a pathway to enhance overall operational efficiency and gain a strategic edge. Whether your focus is on improving supply chain management or optimizing delivery...

by Rob O'Byrne | Feb 13, 2024 | logistics, Videos, warehouse

Logistics KPIs, also known as Key Performance Indicators, remain a widely discussed and crucial subject. Let’s explore common pitfalls that individuals frequently encounter when handling logistics KPIs. Additionally, I’ll guide you in streamlining your...

by Rob O'Byrne | Dec 19, 2023 | Events, logistics, Videos, Webinars

We work with about 200 businesses worldwide each year, giving us insights into current priorities. Today, I’ll focus on the Big Six! Watch the video below to discover more. In it, you’ll find detailed analysis and trends that highlight how these priorities...