ARTICLE SUMMARY

Three rules are really important in inventory management. If you don’t get them right, you won’t be able to do a lot of other things. They are:

1) Observe ABC Classification

It has long been shown that 20 percent of lines account for 80 percent of revenue and margin. These are the A-lines and should be prioritised in the warehouse. The B-lines and C-lines contribute less to revenue so they should not be treated in the same way as the A-lines.

2) Forecast Demand

If you fail to forecast demand, you face the following potential risks:

- Running out of stock

- Excess inventory

- Obsolescence expense

- Hidden costs.

3) Draft an Inventory Policy

If you don’t have an inventory policy:

1) You won’t get consensus

2) Cause and effect will be hard to pin down

3) Systems can’t be set up

4) Comparisons will be impossible.

Three rules are really important in inventory management. If you don’t get them right, you won’t be able to do a lot of other things. They are foundations in a way. Let’s examine each one in turn, likening it to commandment that shall free you from inventory-management sin.

Commandment #1: Thou Shalt Observe ABC Classification

It has long been shown that 20 percent of lines account for 80 percent of revenue and margin.

In a Supply Chain Secrets YouTube video, Kieran Hogan says he has been in the industry pretty much his entire working life and hasn’t seen any place yet where this rule—or something close to it— doesn’t apply.

An example from a company that turned to Kieran for help in cutting its costs and streamlining its warehousing operations will aid in illustrating this maxim.

Let’s call it Company Z.

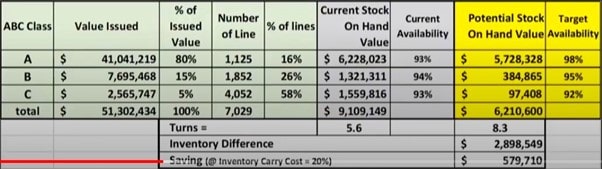

Company Z has a total of 7,029 lines with a turnover of about $51 million (see diagram above). We can break these down as follows:

1) A-lines—Turnover $41m (80 percent of total turnover). Number of lines 1,125. Percentage of lines 16%

2) B-lines—Turnover $7.69m (15 percent of total). Number of lines 1,825. Percentage of lines 26%

3) C-lines—Turnover $2.5m (5 percent of total). Number of lines 4,052. Percentage of lines 58%.

As we work down the lines we see an ever-decreasing contribution to revenue. So if you want to know where to go, where the effort belongs, it’s obviously the A lines.

Let’s look at an example.

Imagine you are a racehorse owner and have racehorses in your stable. You will put all your effort into those that run fast. They get the massage in the morning, they get the best oats, they get everything—and you win some races. If you treat all the horses the same, you’re not going to win races.

The Wages of Sin: Low Turns

If you treated all the lines the same, your turns would be lower because your fast-moving products that account for most of your revenue would not be getting the priority they need.

Another consequence is that your warehouse costs would go up and your availability would go down.

In our example (Company Z), the availability of A-lines is 93 percent, of B-lines is 94 percent, and of C-lines is 93 percent. So the Cs are getting the same amount of attention as the As. This is not unusual. The question is, what do you want the As to be?

Reduce the Inventory, Make Significant Savings

Using our method of discriminating between As, Bs, and Cs, we can project forward and say that if the company does everything to treat the As preferentially they can get as much as 98 percent out of the A-lines.

At the same time, we can project forward and say that Company Z can live on $6 million worth of inventory instead of the $9 million that it is holding.

In real life, the supply chain manager of Company Z did indeed accept Kieran’s plan and knocked $3 million off the inventory.

Warehousing was a significant cost for this company. By cutting back on inventory they reduced warehouse costs by about 20 percent. Taking this and the reduction of inventory into account, overall savings were in the region of $600,000.

Commandment #2: Thou Shalt Forecast Demand

It is important to note that requirements planning is not the same as demand forecasting. You need to do forecasting as well as supply chain planning.

Some other factors to note:

- Forecasting demand is harder than forecasting orders, but if you know your forecast orders your forecasting challenge is diminished.

- Averages are dangerous. Averages don’t tell you anything about change, anything about seasonality, and they don’t tell you much about how quickly things are changing in the market. These days, more than ever, you need to be smarter and look at trends, seasonality, and changes.

- Fashion, taste, and technology are changing rapidly. You need to be able to change product lines fast and effectively.

- Human forecasting is hard, expensive, and often unreliable. You could put your entire sales staff onto forecasting but it will take them a whole day to do something.

Risky Business

If you don’t forecast demand, you face the following potential risks:

- Running out of stock.

- Excess inventory.

- Obsolescence expense. The more stock you have the higher the obsolescence expense. Items are there for longer and are moving slower, and have more time to grow obsolete.

- Hidden costs—e.g. the costs of lost sales.

Commandment #3: Thou Shalt Have an Inventory Policy

An inventory policy is a document detailing the objectives, principles, rules, systems, and processes for cataloguing, classifying, forecasting, planning, stocking, replenishing, purchasing, warehousing, returning, allocating, disposing of, accounting for, monitoring, and reporting inventory.

If you don’t have an inventory policy:

1) You won’t get consensus

2) Cause and effect will be hard to pin down

3) Systems can’t be set up

4) Comparisons will be impossible.

These are the more important aspects of an inventory policy:

- Knowing how the ABCs are calculated and applied

- Knowing the service level objective

- Understanding which of the As, Bs, and Cs are going to be stocked; which are going to be indented (or supplied to order); and which ones are going to be directly shipped.

- Establishing which warehouse gets what. Probably all the warehouses get the As, but maybe you just want to keep the Cs in one warehouse.

- Figuring out how you are going to forecast? Will you use algorithms or are you going to do something simple?

Free Your Shelves from Inventory Management Sin

During his career, Kieran has identified a total of 33 common inventory management traps—or ‘sins’—but the three he has highlighted above are the most important ones. If you don’t get them right, the rest won’t make sense.

If you recognise failings in these areas, I recommend that you take steps to rectify them as soon as possible. Or, as Kieran puts it: ‘Go and sin no more’.

If you have any comments to make or input to offer on Kieran’s analysis, please write them below. If you have not yet subscribed to the Supply Chains Secrets YouTube channel, it would be well worth your while to do so. Every Wednesday we post a new video covering issues central to enhancing supply chain and logistics performance.

Editor’s Note: This post was originally published on November 24, 2020, under the title “3 Common Inventory Management ‘Sins’—And How to Avoid Them” on Logistics Bureau’s website.